How 3D CAD Boosts Efficiency for 2D CAD Users

As a great helper of design, CAD software has been boosting designers’ efficiency for decades. 2D CAD, which came out first, has been widely used in multiple industries. But in the past ten years, an advanced technology, 3D CAD, has emerged and is getting more and more mature, playing an increasingly important role in the design process and co-working with 2D CAD seamlessly to further enhance design efficiency:

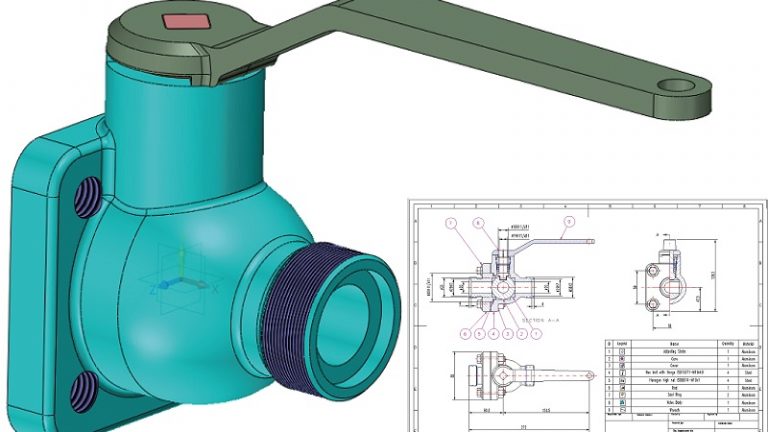

3D CAD is capable of designing and analyzing more intuitively and efficiently, while 2D CAD mainly aids the drafting work, which demonstrates geometric and manufacturing information in a simple, complete, standard and accurate way. They fit in with different stages and different user needs.

In this article, I’m going to show you how 3D CAD can help improve your productivity, and how 2D and 3D CAD can combine to complement each other for the best design experience.

View with ease VS. Imagine with difficulty

As we all know, in the final production, the mechanical part is a 3D object. So if you design it in 2D CAD, facing the 2D drawings, you have to imagine what it looks like in your brain, which is rather challenging. What’s worse, some details could easily be missed, giving you an unwanted “surprise” until the real product comes into being.

But in 3D CAD, everything becomes intuitive. The mechanical part is simulated and rendered in the program, so you can just look around it and make modifications, which can be shown directly and immediately. In short, what you see is what you get during the design process, and you can “foresee” the final products in advance in 3D CAD.

Parametric modeling VS. Manually modifying

During your design, there will always be countless modifications. When you are drawing in 2D, if you want to change some parameters of a part, for example, the radius of a hole, you have to change a lot of other objects related to it because they are non-parametric in 2D CAD. In other words, elements are “separated” with each other, so if you modify one, the others would stay still and you need to change them manually.

On the contrary, in 3D CAD, everything can be parametric. When you are drawing sketches, you can add geometric and dimensional constraints to the objects, so that they can be connected as a whole part. Or you can even define a variable such as X, and insert it in the dimension constraint as the length of the part, which can then be easily changed by modifying the value of X.

What’s more, there is a history manager in ZW3D, which logs almost all your modeling operations. You can locate the operations and features you want to modify by rolling back the history tree or based on the model, redefine them and refresh to get the updated results. Even if an imported model without any modeling history can be edited directly by the Direct Edit technology.

Family part management: All at once VS. One by one

Sometimes you may suffer from the management of a part family. For example, there are a lot of parts with different configuration in the design. Usually, those parts look alike but just with different dimensions, or they are of the same sizes but with some differences in appearance. If you use 2D CAD, you have to create a different drawing for each of the similar parts, which is time-consuming.

But in 3D CAD, with the Part Table, you can just build a basic model, then modify the part parameters to get other parts in the table. In this way, you could easily get a series of parts based on the basic part, which is more convenient and efficient than in 2D CAD.

Printed 2D drawings VS. PMI annotation

After drawing in 2D CAD, you always need to add numerous dimensions to the parts and print the drawings out on the paper, and sometimes the drawings could be blurry because of some printing issues, making it hard for you to check the annotations during production.

That’s no longer the case for 3D CAD, in which all information of dimensions has been stored in the model itself. In the PMI module, you can add annotations directly to the models, which is more intuitive and clearer, and share them with the producers without printing out the drawings.

Combine 3D & 2D to speed up your design

No matter which tool you use, 3D or 2D CAD, it cannot be denied that both of them have their unique advantages – 3D CAD gives you a more direct view of your modelling process, while 2D CAD allows you to add dimensions and annotations, which can be customized according to your practical needs and standards.

So I would recommend combining their advantages by using 3D & 2D CAD both. If they are from the same provider, it’d be better, like ZWCAD, the .dwg compatible 2D CAD and ZW3D, the all-in-one CAD/CAM from ZWSOFT – first you can start modeling in ZW3D, taking the advantages of the powerful parametric technology and the direct view. Then you can export the part drawings to ZWCAD, add annotations and customize their styles as you need.

Embrace the future

3D modeling is the future trend of mechanical design. Its advantages include direct view, parametric modeling, easy management of part families with Part Table, PMI module, etc., not to mention other powerful modules like CAMMoldAssemblySheet Metal in ZW3D, better complementing 2D CAD usage and boosting the overall design efficiency to a new level.